When it comes to aviation lubricants, there's much more than meets the eye. Each product is comprised of multiple components, with each of those components having a complex chemical structure. Chemists like Michael Douglass, Technology Solutions Principal at ExxonMobil, are responsible for understanding the science behind our lubricants.

We spoke with Michael about what drove him to become a chemist, how his science background informs his work today and the various roles he has held during his 23 years with ExxonMobil.

What is your current role at ExxonMobil, and what are your responsibilities?

I am the Aviation Lubricants Technology Solutions Principal in ExxonMobil Technology & Engineering (EMTEC). I formulate and support jet oils for aviation engines, and I also formulate and support hydraulic oils for aviation.

What inspired you to pursue a career in chemistry?

I liked science, and I liked synthesizing things in the lab. And I remember one of the things my undergraduate advisor told me — depending on what type of chemistry you're going to do, of course, something like nine out of 10 experiments are probably not going to work or not work the way you expect them to. So, you have to be happy enough about the ones that do work so that you're not discouraged by the ones that don't. That really stuck with me and is one of the reasons I decided chemistry was the thing that I wanted to do. I got excited enough about the stuff that worked, but I didn't get totally deflated about the things that didn't.

What led you to pursue a career at ExxonMobil?

A lot of people with advanced chemistry degrees decide they want to teach or to make something that’s never been made. That’s important work that people should do, but I wanted to do something that I could see was being applied out in the world. I wanted to use my chemistry knowledge to support real-world changes, making something that worked better or was cheaper or was higher performing, that a customer could actually buy and use in the real world. ExxonMobil offered that opportunity, although I didn’t know I was going to work on Aviation lubricants when I first decided to come here.

When did you join ExxonMobil, and what were some of types of projects you worked on at the time?

I started with ExxonMobil directly after grad school in 2001, soon after the merger, so it was like being in the first class, with a lot of new employees from campuses to work for the newly merged company. My first job was actually in Aviation lubricants, and some of the things I was doing are similar to what I'm doing now. I was supporting jet oils and also piston engine oils, which are the types of oils you use in smaller aircraft that hold four or six people. I would look at how we might improve our existing products or better support them, as well as the types of new products we might want to produce. If a customer had an issue, I would troubleshoot, looking at the engine they’re using and how the oil was performing. Other areas I’ve worked within ExxonMobil are related to planning as well as intellectual property, where I would read patents and support the company’s legal teams across a variety of product areas. My career at ExxonMobil hasn’t been linear – I’ve moved around different areas related to the lubricants business over the last 23 years, but for about 15 years I have had varying levels of interaction with Aviation.

Do you perform research for all ExxonMobil Aviation lubricants products (oils, greases, hydraulic fluid, etc.)?

Our lubricants scientists interact a good deal across product lines. But specifically, I support jet oils and hydraulic fluids, for aviation applications in both cases.

As a chemist, what, specifically, interests you about aviation lubricants?

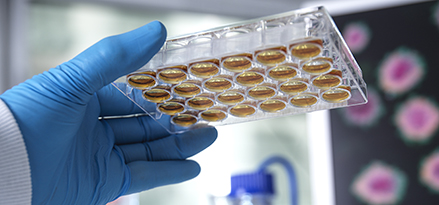

One of the things that's interesting about it from a chemistry standpoint is aviation lubricants are formulated from components, so you need to know the detailed chemical structure of each component of the lubricant. You need to know and predict how components will interact with each other to provide the performance you are trying to provide. You don't buy a combination of chemicals from a particular supplier and say, poof, I'm finished. You actually have to pick out this component, and this component, and this component from these different suppliers and put them all together. So, from a chemistry standpoint, you're down into the exact structures of the molecules you use. So, I like that, from a chemistry standpoint.

One of the things that's challenging is that, with aviation lubricants, not only do you have to approve the lubricant, but you have to approve the place you make it. In order to open a new plant in Port Allen, Louisiana, for making aviation lubricants several years ago, we needed to do years of work before that to get the different components approved for different places that they were going to be made, and then we had to get the plant itself approved. Getting the plant actually open and running was a very satisfying experience from my perspective.

What are the primary challenges that you face when developing/improving aviation lubricants to better meet the needs of aircraft as they evolve, and why?

The aviation industry is highly regulated and slow to change. For jet oils, there are a lot of limitations on what kind of materials you can use to make the lubricant, so the challenge is getting the performance you want with a small toolbox of materials. The oils have to withstand higher temperatures. And that's what Mobil Jet Oil 387 was designed to do – withstand these higher temperatures. We have a top-of-the-line product that you can use to lubricate future engines.

For hydraulic oils, some additives used are under regulatory scrutiny, so the challenge is making oils that provide the needed performance without causing concern from a toxicological or environmental standpoint. Some U.S. states and even some countries ban, or consider bans on, some of the chemicals that lubricants suppliers have depended upon so their products can protect aircraft components from erosion. As a result, we continue to look for substitutes that perform the same functions. The timing of these bans should be interesting because it can take about a decade to get new products, new formulations, approved. That means, if a regulator says they want to phase out a certain chemical over the next 12 years, you really have about two years to come up with something to replace it.

How has the aviation market and ExxonMobil’s Aviation lubricants business changed over the past two decades that you’ve been with the company?

ExxonMobil has about half the jet oil business, which has not changed much in the last two decades. We are supporting our newest oil — Mobil Jet Oil 387 — and competition is slowly evolving to provide a few new products that are meant to compete with MJO 387. The evolution of new products in aviation is very slow.

In hydraulics, the newer airplanes have higher pressure hydraulic systems, and our newest oil, HyJet V, has outperformed the competition in these systems, so ExxonMobil is well-positioned right now. HyJet V was just finalizing some of its approval testing in the early 2000s, and now it's one of the most used hydraulic fluids in the aviation world.

The aeroderivative market also uses aviation lubricants. Is that a big opportunity for ExxonMobil Aviation, and do you need to make any changes to your products in order to serve that market?

That’s a market we’re looking to expand. It’s not a huge market but there has been some slow expansion. Aeroderivatives are what the name says — it's an aviation engine, but it sits on the ground. You need the same sorts of approvals for an aeroderivative lubricant that you need for an aero engine — the formulations are the same and the specifications are the same. One of the big differences is that, in an airplane, you’re always conscious of weight. You can’t just have a 500-gallon sump of oil, since you’d have to fly it from place to place. Another difference is that with airplanes you’re constantly topping off with fresh oil to get ready for the next flight.

With an aeroderivative turbine, the specifications are the same, but the problems are a little bit different. You can use large drums of oil because the engine isn’t going anywhere. And you can use the same oil for year or a couple of years. Unfortunately, oil in aeroderivative engines absorbs moisture from the air, so keeping these things dry is a challenge. A client isn’t going to want to flush and refill because we’re talking about hundreds of gallons of oil. That’s why we developed the Mobil Jet™ Oil CI product, which has additional additives for improved protection against rust and corrosion.

What are you working on at the moment?

In the area of new products, I am working on new jet oils with potential military applications. I am also working on new additives for hydraulic oils.

There is a constant need for support for our blend plans and support for our marketing team, so that support is part of my role as well. There is also always a drive to have more flexibility in the oils we make as far as the suppliers of the additives we use, so I also play a role in approving alternate additive suppliers.

I also have significant leadership responsibilities in industry groups, both the SAE E-34 for jet oils and the SAE A-6 for hydraulic oils.

What’s your favorite part of your job?

I like being able to explore new additives, to see if we can accomplish something that has not been done before, using something that has not been used before. It's a small part of my job because aviation changes very slowly, but it is one of my favorite parts of my job – actually making something new.

Mobil Jet™ oils

Hear from our experts

12/1/2023